The need for accuracy in your cement mix ratio hinges on the durability of your concrete. Getting your cement mix ratio right and knowing how to mix the concrete correctly helps to ensure your job will last long.

What Is Concrete?

A building material which comprises the mixture of cement, gravel or broken stones and sand with water and gets hardened with time is referred to as concrete. Its vast application in construction work makes it essential to understand the recommended quantities of the materials needed in the concrete as found appropriate for a particular use.

In this respite, it is essential to consider the possible strengths of concrete which range from C40 down to C10. C40 is regarded as the strongest possible and C10 is regarded as the least strong.

What’s The Best Concrete Mix Ratio For General Domestic Jobs?

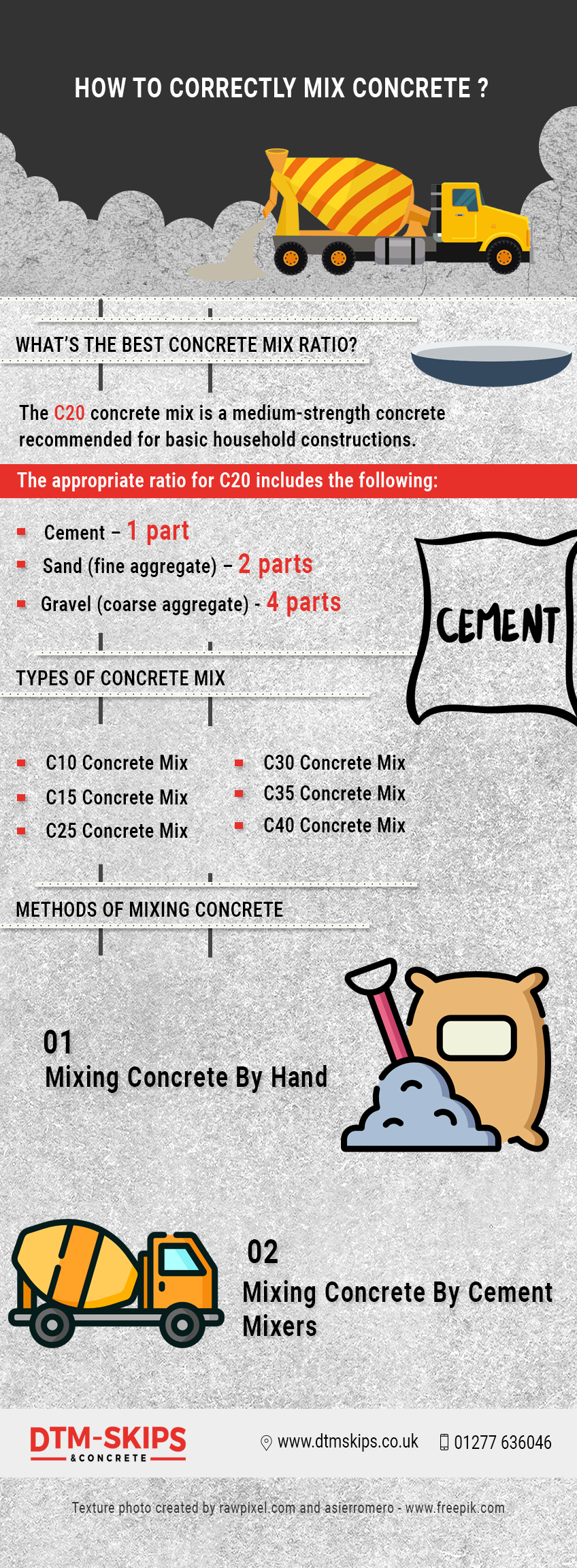

The C20 concrete mix is a medium-strength concrete recommended for basic household constructions such as retention of posts, garden walkways and many more. This cement and sand mix is, however, not recommended for use in constructing a foundation and other construction works that would need super resilient concrete.

If you have any major structural adjustments or construction project, the architect, quantity surveyor or a building control officer should recommend the concrete strength to be used. This will be based on some parameters they will have to explore.

The appropriate ratio for C20 includes the following:

- Cement – 1 part

- Sand (fine aggregate) – 2 parts

- Gravel (coarse aggregate) – 4 parts

When premixed ballast is required, then 6 parts are required for 1 part of cement.

Ideally, the water to be used should be 55 percent of the net weight of the cement if all other materials will be delivered absolutely dry. However, in reality, the materials are usually damp, especially the sand. You may then have to reduce the quantity of water added.

Fixing a small fault in your fence definitely does not need up to a bag for the cement mix. So it may be a waste if you will not be using what is left anytime soon. Check the DIY shed in your neighbourhood if they have ready mixed mortal stock of DIY concretes which may be appropriate for the repair.

What Are The Precautions You Should Take?

Cement is not the best of powders for your skin. So, you have to be mindful while working with it. You should wear protective clothing and make use of appropriate materials.

Ensure you take adequate precautions while adding water because the volume of water to be added is an estimation.

What Other Strengths And Types Of Concrete Mix Can You Have?

Various strengths and types of concrete mix are available based on the recommended use. The role the concrete is to serve is the most important factor considered before a type of concrete can be chosen.

- C10 Concrete Mix

- C15 Concrete Mix

- C25 Concrete Mix

- C30 Concrete Mix

- C35 Concrete Mix

- C40 Concrete Mix

What materials do you need to make a concrete mix?

- Aggregates: You can request a lorry to deliver aggregates to you after buying it loose. Another option is aggregate that is ready-mixed cement, which can be bought from builders’ merchants. It is generally cheaper if you buy it loose. But, check with your local merchants. They may also have great deals for you. A ballast is a mixed aggregate which contains small stones and sharp (or grit) sand.

- Cement: Bags of cement come in either 25kg or 50kg and can be gotten from builders’ merchants. Cement is made from limestone, which undergoes many steps of processing.

- Water: This is indispensable in making concrete. Despite its importance, it is not needed in abundance. Only the calculated volume of water is needed to ensure the concrete comes out strong.

How To Mix Concrete

Proper mixture and combination of materials are essential to have good concrete. It is kind of tricky when ensuring appropriate quantities of materials are used. The ballast or aggregate will heap well on the shovel but the cement will not because it will slide down the heap. Meanwhile, 1 part of ballast has to be the same as 1 part of cement.

It is then recommended to use a bucket or headpan instead of the shovel to prevent errors in measurement.

Methods Of Mixing Concrete

Mixing can be done manually with your hands or a concrete mixer. If you are going to be preparing more than one batch of concrete, ensure that they are equally wet. Otherwise, the concrete will not get dry evenly. This may leave some cracks and shrinkage in your concrete.

1. Mixing Concrete By Hand

This is okay if it’s a small quantity of cement. Otherwise, you may not be able to mix it thoroughly enough, and the quality of the concrete may turn out bad. So, you need to know how to mix cement.

If you ever have to mix with your hands, you should follow these steps:

i. Cover up your work area with a tarp or any other suitable material. You may also use a mixing board that can be reused. You can also improvise with a piece of wood.

ii. As explained earlier, deploy the use of the ratios and consider the precautions. In the recommended ratio, put the materials at the centre of the board or on the tarp.

iii. Mix the aggregates and the cement thoroughly till you have a uniform product – the aggregate blended well with the cement. Scoop your pile of the mix on another side of the board. Break lumps while you work your way through the pile, gently heaping a scoop over the other.

iv. Collect the mixture together in the centre of your work area and then scoop out the required amount of cement.

v. Sprinkle around a third of the cement over the top of your pile and then mix by folding as you did above until cement is mixed thoroughly and then repeat the process another two times for the remaining two-thirds. If there are any lumps, break them up finely. The most important part of this is ensuring the cement is evenly mixed with the sand and aggregate.

vi. Spread out the pile to make a hollow at the centre. The hollow area is to hold the water you are to use. Just only a third of the estimated water to be used should be added.

vii. Working around the heap, slowly scoop from the outer side of the mix into your hollow crater with water. Mix it well with the water by running your shovel through or hand trowel.

viii. Make it into a pile again and have your hollow at the centre, add the second third of water then work your way around it like the first time.

ix. Sprinkle the remaining water over the mix, turning it inside out as you do so. This should be done until the “molten” mix is uniformly saturated with water.

2. How To Mix Concrete With Cement Mixers

You can hire a cement mixer. If you do a lot of cement mixing, it could be more economical in the long run to buy one. If you no longer need the mixer, you can sell it.

A mixer gives the best quality of mixes as it thoroughly churns the concrete to give a uniform product with no stress. Mixers are available in different volume capacities.

To use the mixer, you need to take the following steps:

i. To prevent messing up the floor, you should cover the area with a tarp and position the mixer in the middle of the area. Connect it to a power source using a suitable extension cable. Turn it on to ensure it is working.

ii. Start by filling with three-quarters of the water required for the concrete, then add half the quantity of gravel and sand.

iii. You should be conscious of not putting the shovel fully into the rotating mixer as you add your materials. The mixer could overpower you and twist the shovel out of your hand. The end of the shovel can hit you while it rotates with the mixer. So you should learn to throw the materials into the mixer without the shovel extending into its drum.

iv. After that, add all the cement needed. Cement is like dust, and while you turn it into the mixer, you could get a cloud of lime which can irritate your skin and eyes as well as make you cough.

v. Finally, add what is left of your sand and gravel. Then, leave the mixture to churn for half a minute before checking to see if the water is enough.

vi. If need be, add only a small quantity of water each time while watching out for the consistency and leave it to mix for about a minute before adding water again.

vii. You may also use a sprinkler to wet the concrete and try to gauge the quantity of water you are adding. Never use a hose to add water to a cement mixer.

viii. When the concrete has mixed up satisfactorily, empty the content of the mixer into a wheelbarrow by tilting the drum of the mixer slowly. Try and get out everything in the mixer. You can use a hand trowel to clean it out when the mixer had stopped, of course. Rinse out the drum with water when you are done mixing.

A slump test can be carried out to check out the quality of your mix.

How Do You Protect Your Concrete Until The Concrete Is Cured?

Depending on the condition under which you’re working, there are measures you need to understand to help your concrete cure well.

Generally, when your concrete dries too fast, it leaves your concrete with cracks. It will also be weaker than it ought to be. But when it dries out slowly, it tends to come out stronger.

However, in freezing temperatures, your concrete cures really slowly but this doesn’t mean it would be stronger. The water in the concrete freezes and reduces the binding capacity of the cement. So when the weather gets warmer and the ice pieces lodged in your concrete melts, it leaves your concrete with many minute cavities. These cavities limit the strength of your concrete.

Hence, you have to target optimal temperatures to work under to get the best result. But, if you cannot wait for favourable weather, you can do the following depending on the scenario:

- On hot and dry days, let your concrete dry up till it is a little firm. Then, cover up with plastic sheets or bubble wrap to reduce how fast it dries.

- On cold days, you can cover with blankets to keep warm and prevent the water from freezing. You may also decide to work in the warmest time of the day, so the concrete is firm enough before the cold.

Conclusion

The right composition of your concrete with the materials in the recommended ratio is instrumental in having good concrete. Using a proper mixing technique and helping your concrete cure well will also make the concrete durable.